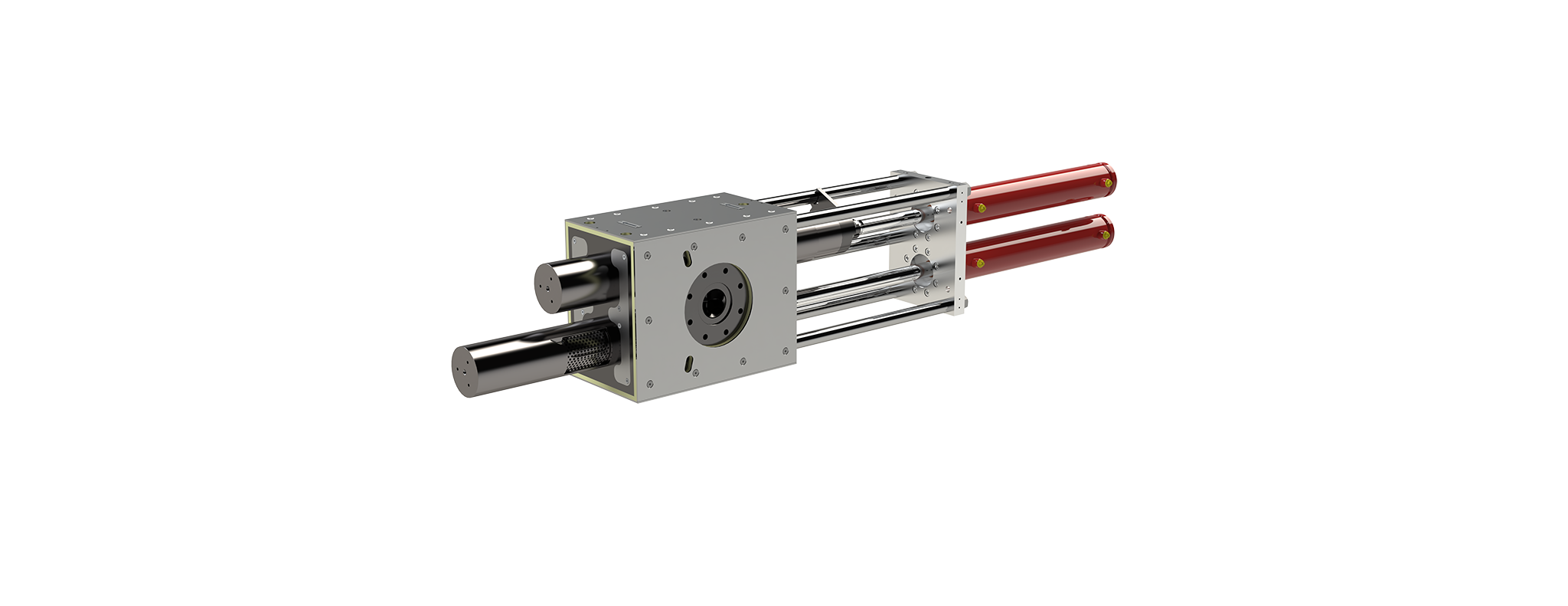

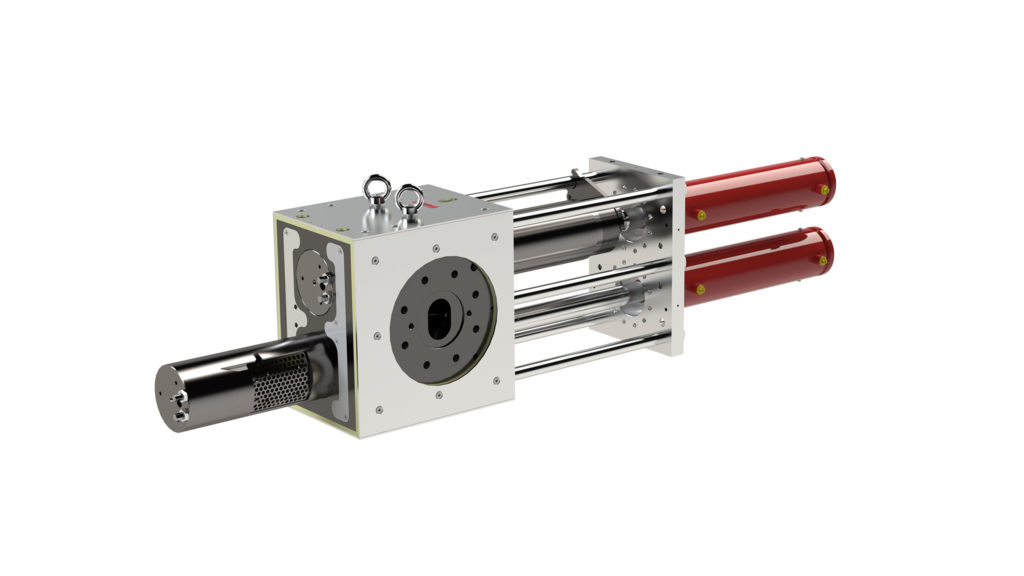

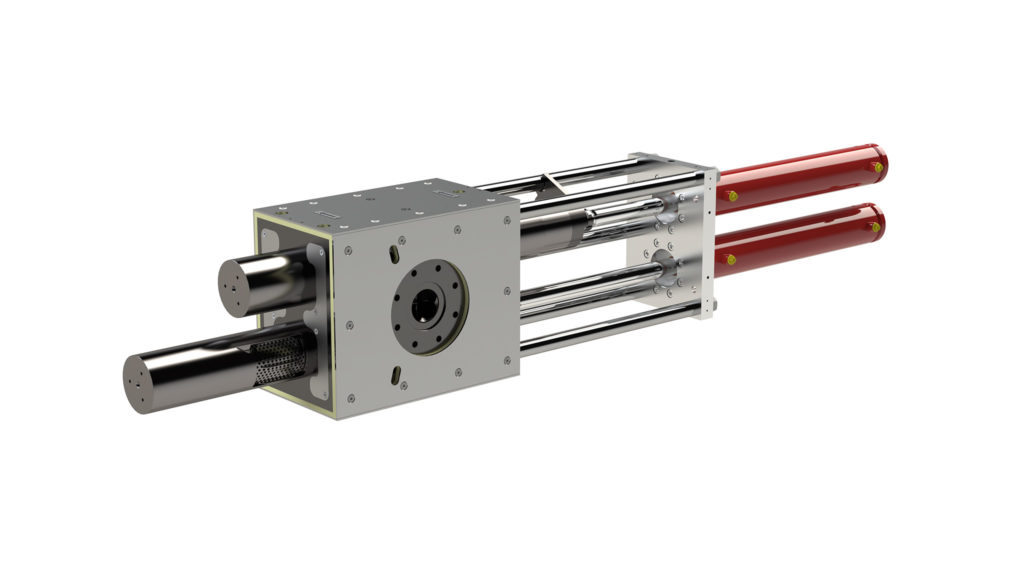

Screen Changer TSK-RS / TSK-XRS

Backflush Screen Changer with two or four screen cavities

Trendelkamp continuous screen changers are designed to meet the highest quality demands in polymer melt filtration. TSK RS and TSK XRS screen changers are based on the robust and proven duel bolt system design and guarantee safe and reliable operation.

- For continuous application without interrupting production

- Dual bolt design with two or four screen cavities

- Continuous with fully automatic self-cleaning and hydraulically assisted operation

Advantages:

- Fully automatic self-cleaning

- Saving screen costs

- Extended production times

Features:

- Filtration size up to 1.748 cm²

- Process pressure and temperature up to 350 bar / 350 °C

- Differential pressure of the breaker plate up to 100 bar

Application examples:

- Extrusion

- Compounding

- Recycling

Recycling options:

- Oil, fluid or steam heated

- Protection against corrosive or abrasive materials

- Stainless steel design

- High temperature designs up to 450 °C

- ATEX-design for hazard areas

Your Contact persons

Marius Gerdes

Sales Manager

Todd Reed

Trendelkamp L.P. (USA)