Screen Changers

from Trendelkamp

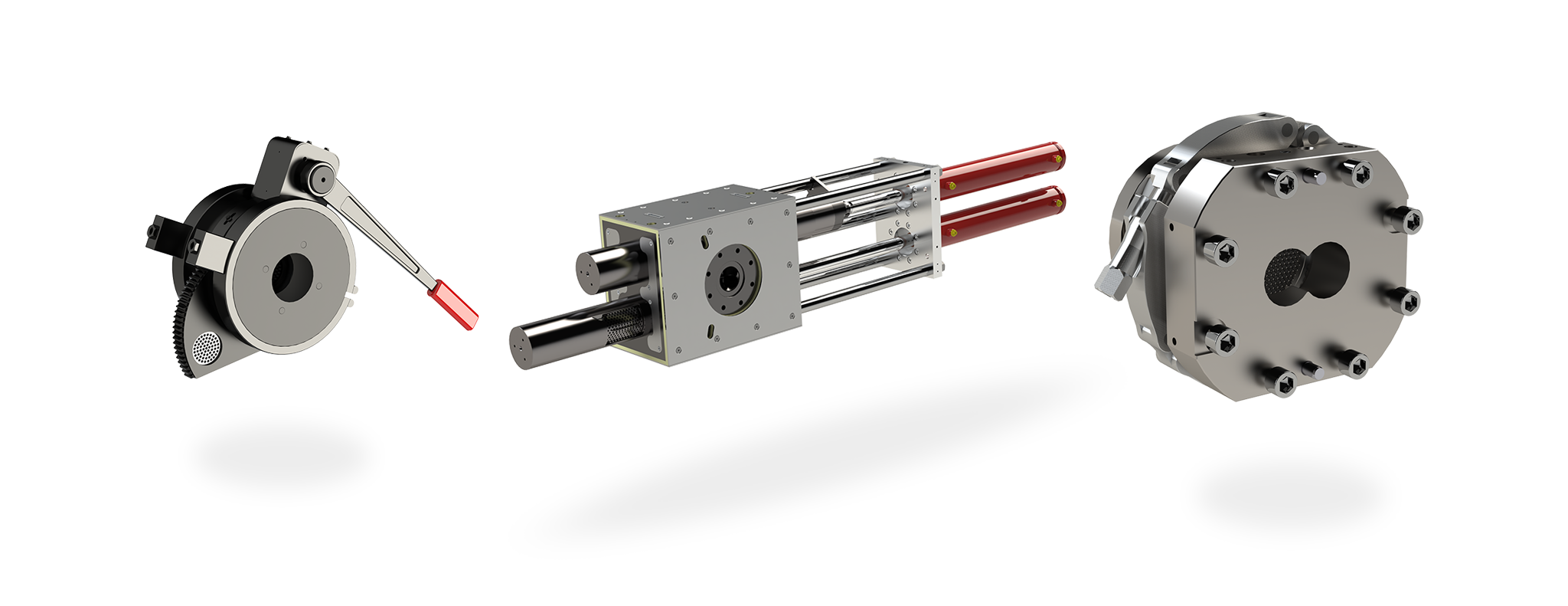

Trendelkamp is your contact for filtration in the plastics industry. With decades of experience and know-how in extrusion, Trendelkamp can design and supply you with customized filtration systems. Our product portfolio includes simple discontinuous manual screen changers up to fully automatic backflush screen changers. For years we have been a reliable partner to leading manufacturers of extrusion lines, plastics producers and processors with our filtration systems.

- Operator friendly

- High product quality

- Durable and low maintenance machines

- Planning and implementation of individual complete systems

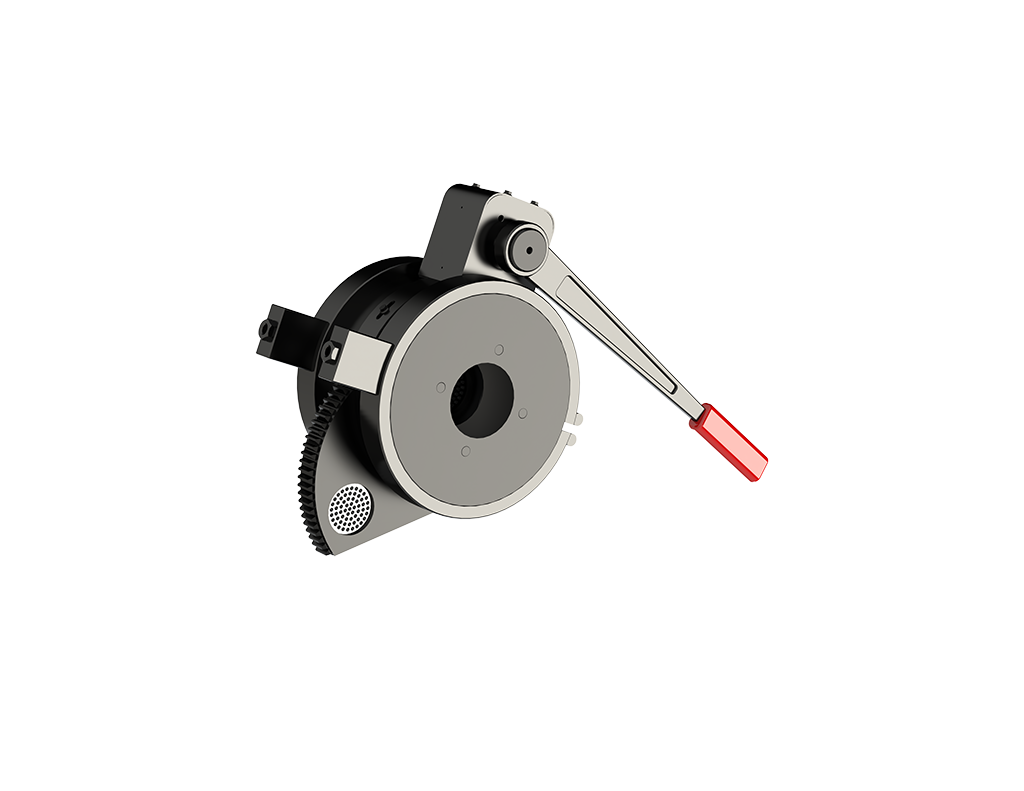

- For small production and lab lines

- Two-piece adapter with one screen cavity and quick release C-clamp connection

- Discontinuous and manual operation

- For small production and lab lines

- Swivel plate design with two screen cavities

- Discontinuous and manual operation

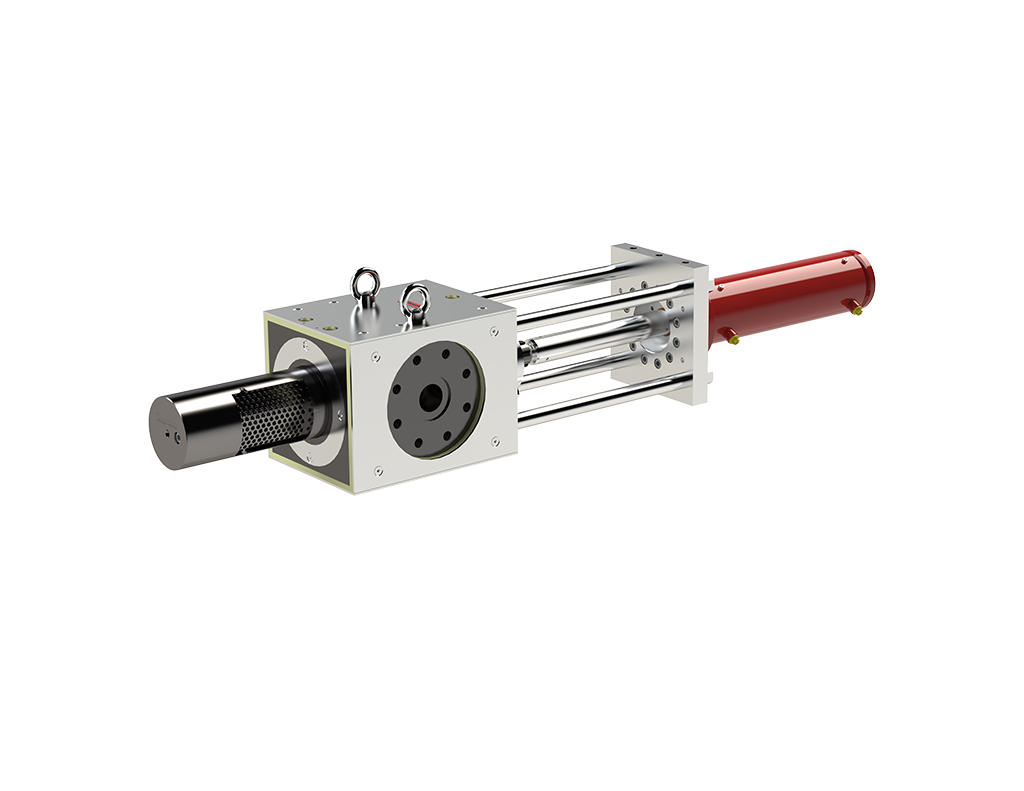

- For applications that allow a short-term interruption of production

- Single bolt design with one screen cavity

- Discontinuous and hydraulically assisted operation

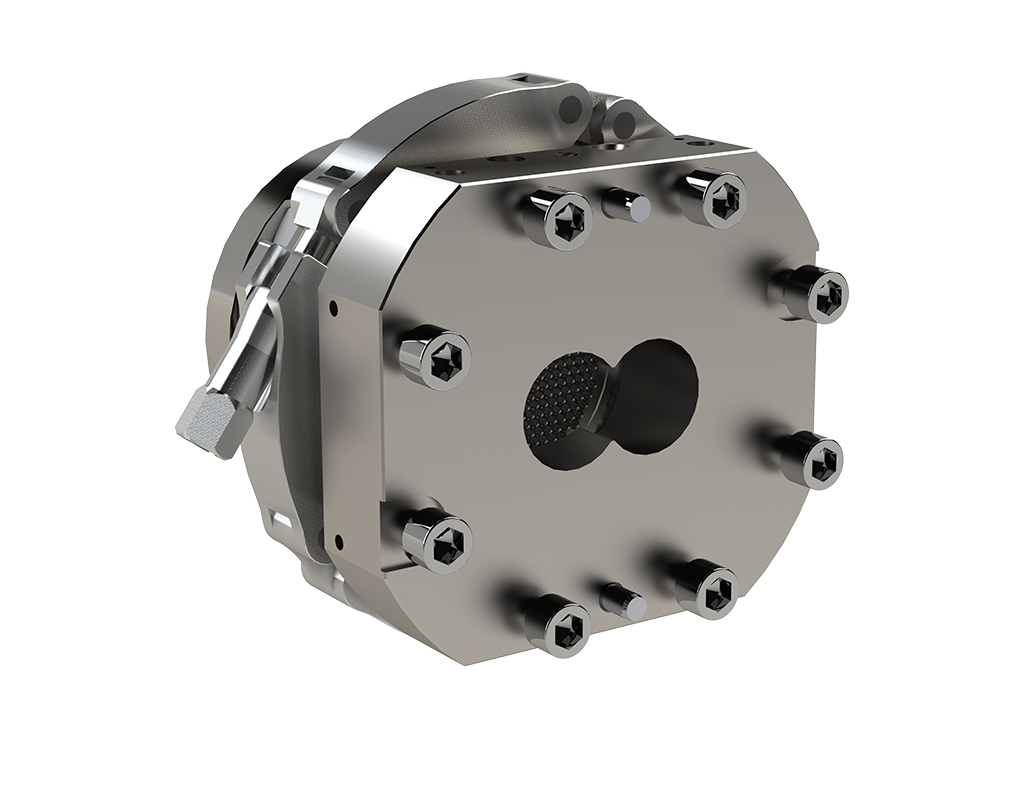

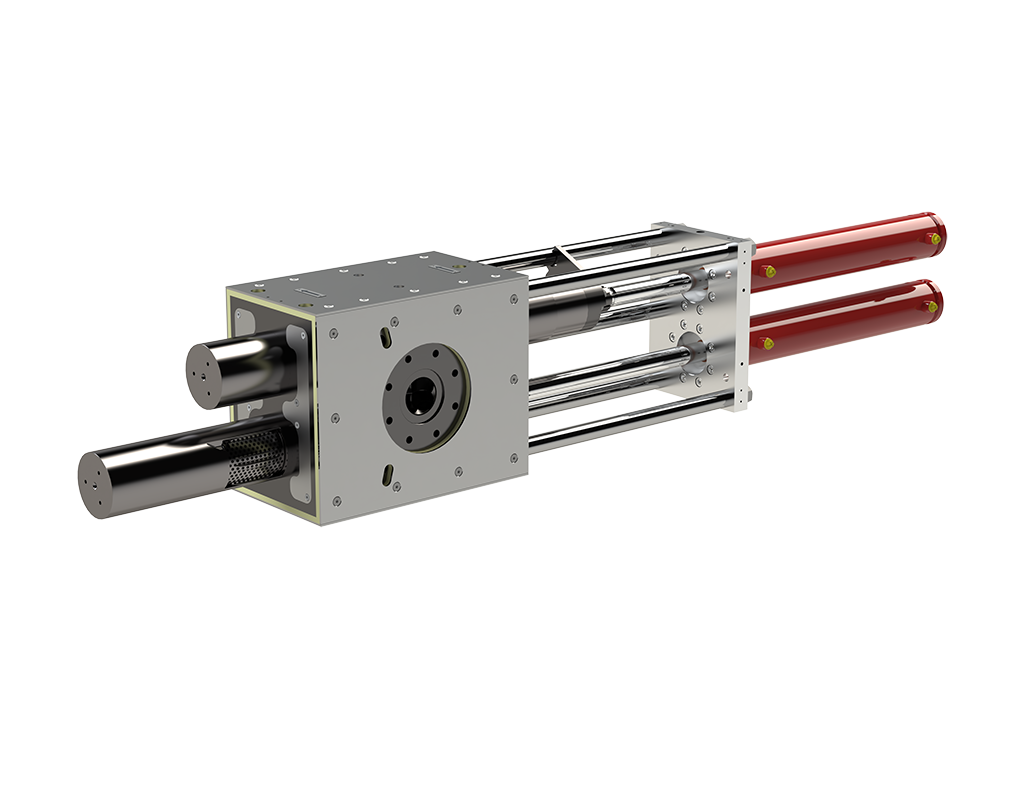

- For continuous application without interrupting production

- Dual bolt design with two screen cavities

- Continuous and hydraulically assisted operation

- For continuous application without interrupting production

- Dual bolt design with two or four screen cavities

- Continuous with fully automatic self-cleaning and hydraulically assisted operation

Your Contact persons

Marius Gerdes

Sales Manager

Todd Reed

Trendelkamp L.P. (USA)