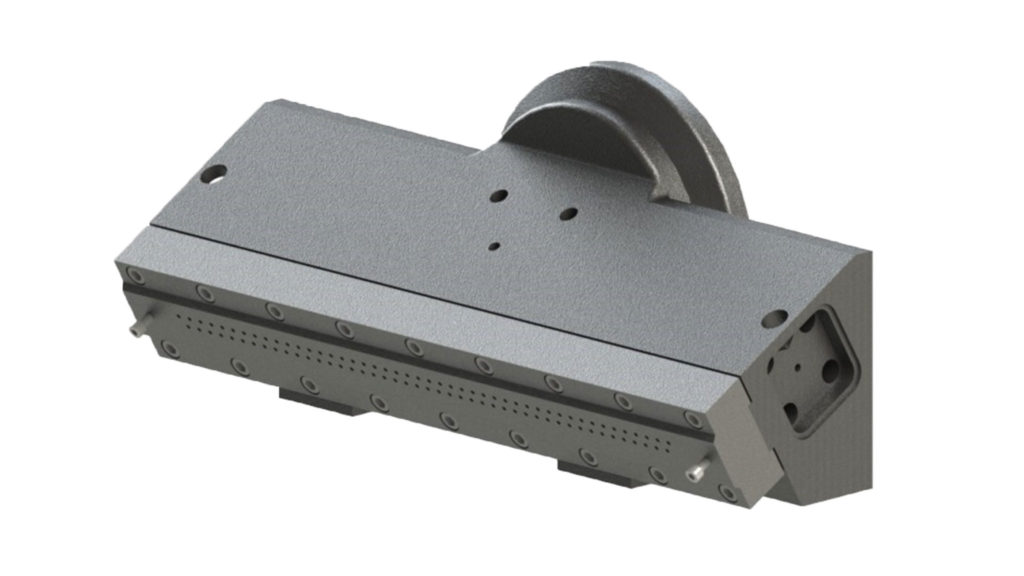

Strand Die TK-D

The strand dies of the TK-D series are a downstream equipment from the screen changers and extruders.

A rheological optimized flow channel guides the entering homogeneous melt to the nozzle bar. The nozzle holes divide the melt stream into melt strands. The strands are cooled by water or air in a strand cooling trough or on a strand conveyor belt.

- Robust and low-maintenance design

- Rheological melt distribution

- Applicable in different applications

Advantages:

- Customized connection flanges

- Rheological designed flow channels

- Exchangeable strand die plates

Features:

- Number of strands tailored to the process

- Process pressure up to 150 bar

- Process temperature up to 300 °C

Application examples:

- Compounding

- Masterbatch

- Recycling

Options:

- Oil, fluid or steam heated

- Protection against corrosive or abrasive materials

- Stainless steel design

- High temperature designs up to 450 °C

- ATEX-design for hazard areas

Options (Design):

- Insolated design

- Swivel device for die

- Quick connections with C-Clamp

- One- or two-part die body

- Single or double row die plate

Your Contact persons

Marius Gerdes

Sales Manager

Todd Reed

Trendelkamp L.P. (USA)